OUR MARKETS

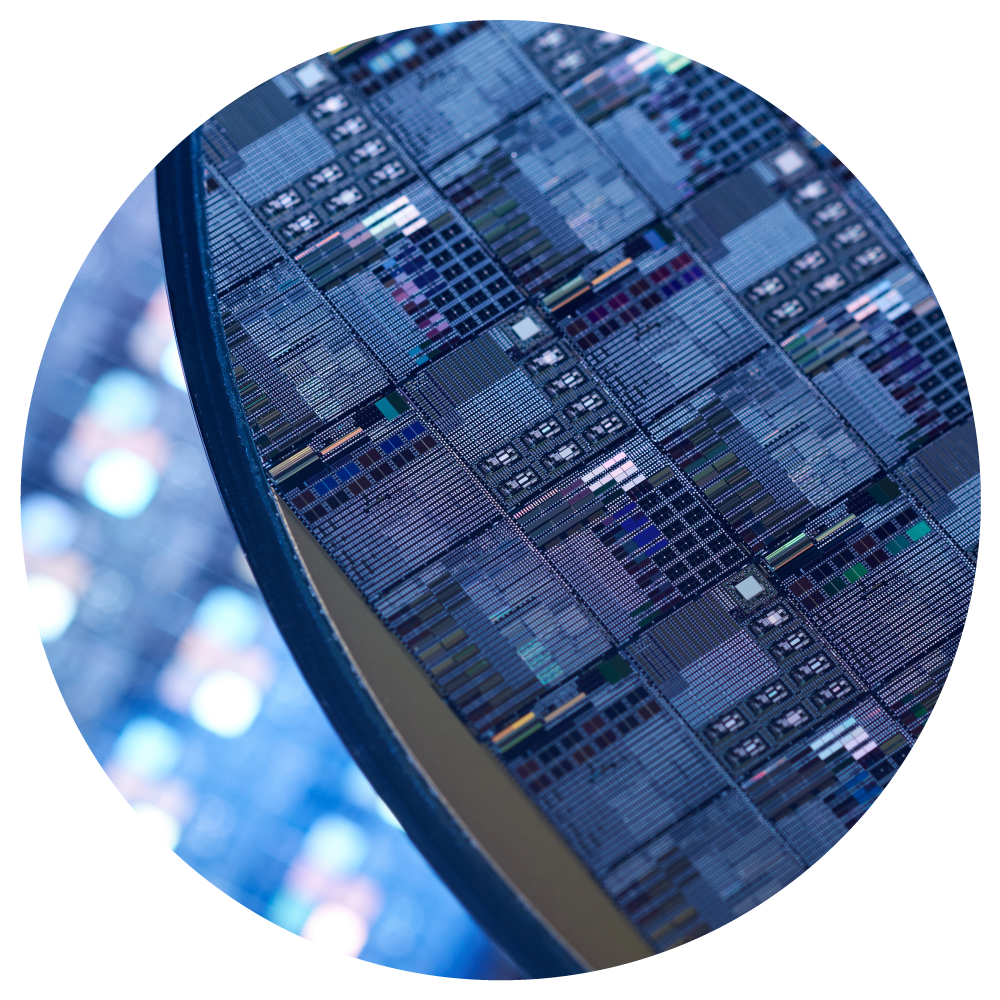

Silfex's silicon components have applications in the semiconductor and optical markets.

For markets that require advanced materials fabrication with tight tolerances and precision process control, we have a solid foundation based on years of experience in the semiconductor and related industries. We serve both established and emerging sectors for low- to medium-volume and high-mix manufacturing needs.

For markets that require advanced materials fabrication with tight tolerances and precision process control, we have a solid foundation based on years of experience in the semiconductor and related industries. We serve both established and emerging sectors for low- to medium-volume and high-mix manufacturing needs.

SEMICONDUCTOR PROCESS EQUIPMENT

The largest semiconductor equipment companies rely on Silfex to deliver the critical silicon components needed to meet their customers’ stringent device requirements.We serve most of the major segments of the semiconductor processing equipment market, including etch, PVD, test, ion implant, and thermal processing. We also follow the highest standards in business practices, emphasizing confidentiality and IP protection. Our team of expert machinists and engineers consistently deliver the highest quality components in the quantities needed.

Semiconductor process equipment applications include:

1Etch

- Critical gas distribution

- Wafer edge rings

- Plasma distribution products

2Ion Implant

- Shield rings

- Liner sections

- Electrodes (rods)

- Machined parts

3PVD

- Silicon targets (bonded/non-bonded)

4MOCVD

- Susceptors (wafer disks)

- Rings

OPTICAL MATERIALS

We help customers with infrared optical technology needs, supplying raw material and custom silicon components such as precision mirrors and lenses, optical connectors, and custom designs to exacting specifications. Our large inventory of ingots and blanks also helps us fulfill orders for typical material requirements quickly.Optical Applications

- Custom ingot growing utilizing high purity polysilicon and Magnetic Czochralski (MCZ) process technology

- Specialty precision components for advanced communications and satellites utilizing silicon, silicon carbide, and other materials

- Raw material and consulting with our engineering experts

- Complex, ultrasonically machined patterns in silicon mirrors

Our engineers use innovative and cutting-edge technologies and processes to create our components. Read more about how they do it on our Processes page.

OTHER HIGH TECHNOLOGY MARKETS

For build-to-print or custom precision components for most markets, we leverage best-in-class engineering and manufacturing expertise to deliver innovative, custom silicon components.We work with private industry, laboratories and high-volume OEMs from concept and feasibility to full production on a variety of custom components. Between our two facilities, we offer in-house silicon growing, silicon ingot slicing and processing, and state-of-the-art machining capabilities.