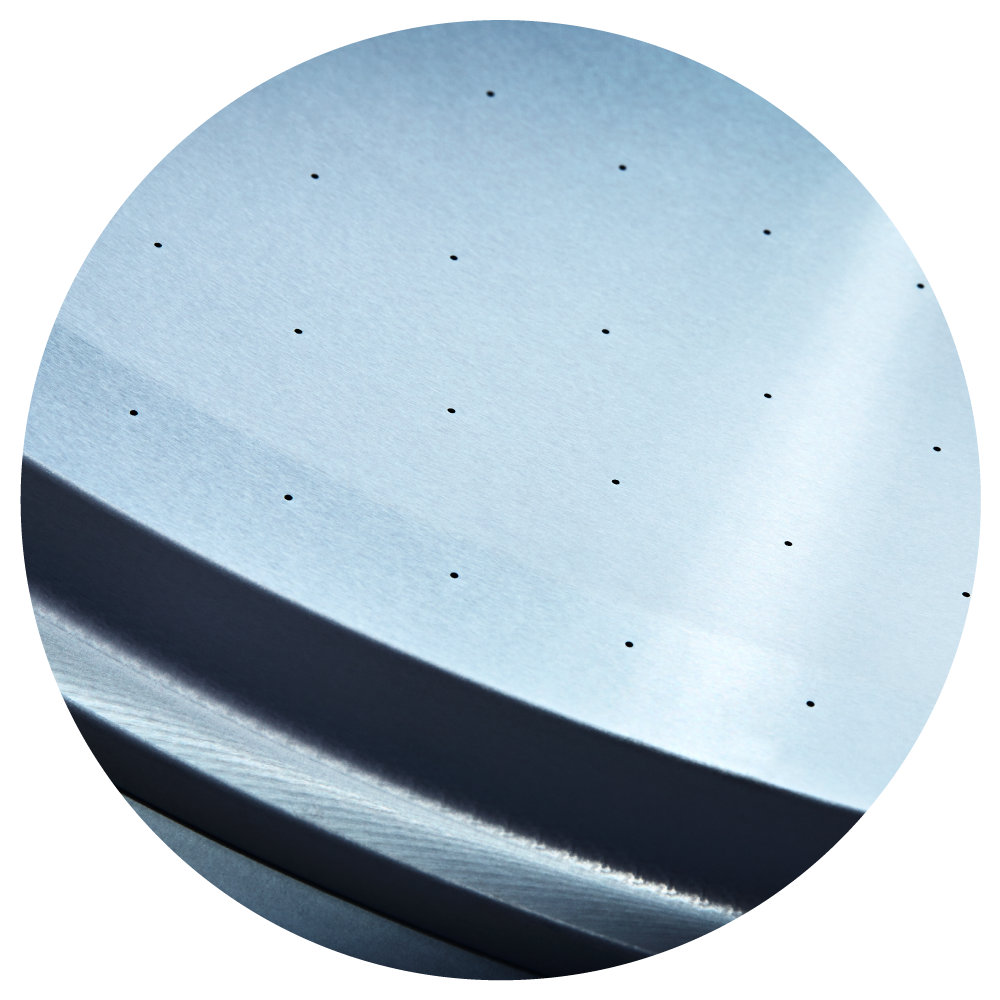

Silicon Small Hole Drilling

What makes us better

Our silicon micro-machining operations specialize in small hole drilling with zero subsurface damage and micron level roundness for diameters. Silfex’s proprietary hole making and slotting processes guarantee shape accuracy, surface quality, and dimensional accuracy of our silicon components.

The accuracy of our small hole drilling captures exact specifications at micro levels, ensuring a superior product.

Capabilities

- Diameters: as low as .011” (0.28mm)

- Surface finishes: <1Ra micro-inch