Silicon Lapping and Polishing

What makes us better

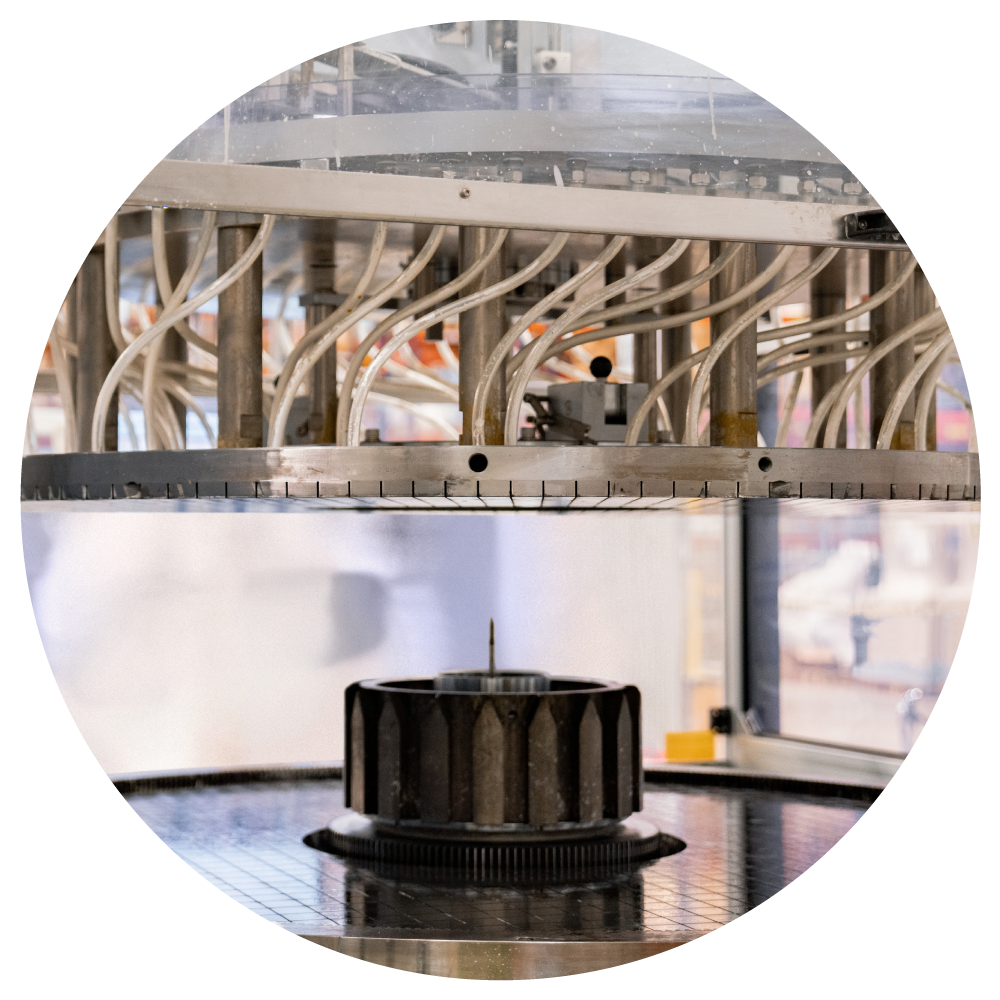

Precision, repeatability and uniformity are the keys to our lapping and polishing techniques – once machined, flat silicon electrodes are lapped to customers’ exact thickness and surface roughness specifications, reliably and consistently meeting tight tolerances. State-of-the-art, 3D polishers take finishes to the next level for extreme smoothness and a glass-like finish to our silicon components.

Tried-and-true techniques have been refined over our company’s lifetime for consistent flatness, parallelism, and thickness, in addition to optimal surface roughness and minimal depth of damage. When complete, we inspect every component to ensure they meet customers’ final specifications.

Capabilities

- Polished finishes of .4 micro-inch Ra or better

- Flatness: <0.0005"

- Parallelism: <0.0010"